The Myth of Standard Work

- rkunst5

- Jun 26, 2022

- 2 min read

One of my great Sensei’s, mentors, and a key member of our team came to Gadget Manor this weekend and of course the conversation turned to Enterprise Excellence and ultimately Standard Work.

He explained that the fundamental flaw with organizations attempting to apply standard work is that they do not understand a basic fundamental principal … when you look at the available time of an individual, the closer the individual is to a machine the greater the percentage of the available time should be devoted to standardized work … Ahhhh!

This makes so much sense … as he works with individuals … once he has the critical mass mapped, then you can begin to synchronize the team into a common cadence … even though the President only has a component of 5% of standard work and the line-side team member is at 95%.

The forms and templates used are simple robust and act as a monthly report and checklist. Once again it follows a standard Toyota template used for other activities so the learning curve and use by team members is dramatically reduced.

So we know that teams have game plans and practice them often. When I speak and work with teams it is amazing how the majority of folks follow a very exact standard work pattern up to the time they arrive at work and then it seems to fall apart. Now with this new template and methodology you can co-mingle standard work with business deviations.

Once again, it was interesting to hear the horror stories of how folks resisted to adopt standard work especially in leadership roles, but once they have completed the process how they appreciate the benefits.

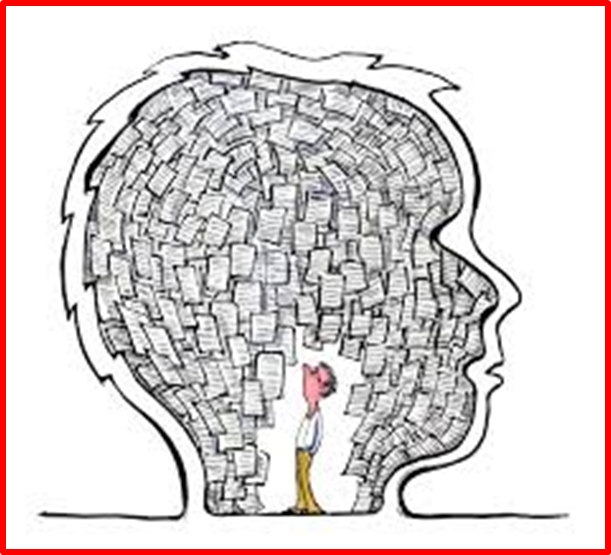

This really resonated with me. Why?, Many years ago i was involved in a study group facilitated by Toyota where they felt that Innovation was being stifled as a result of a dominance of Standard Work. In the result they found that people had to find a balance between "Tactile" activity (what is required to produce your 100 tons of coal each day) and "Strategic" ... where you need to focus on infrastructure development and market growth.

After lessons learned, we applied the implementation of Standard Work into several organizations and to our biggest surprise it really helped create employee alignment and synergy which by surprise showed up in accounting as the organization was able to close month-end results within 24 hours instead of the 7 days prior to standardization ... why?, because we were able to synchronize the need for al data submissions across all facets of the organization.

We now have this resource available to coach organizations about how to implement and benefit from this advanced tool of standardized work. It really is very cool and will enhance the effectiveness of your other enterprise excellence tools.

Comments